Back when I made The Kinfeld, I shared how I built a Mansard roof. Click HERE to see.

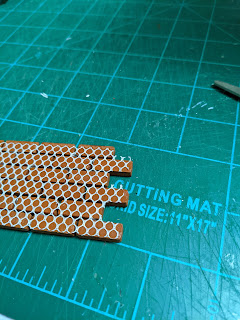

I decided to use the same technique for the roof shingles as well. Click HERE for my shingle tutorial.

This project is just about finished. On the list is a few touch ups with paint and the installation of an old fashioned house elevator/electric. This was made to be a way to display a collection of miniatures more so than to mimic a realistic home.

The beautiful windows and door embellishment really make it feel grand and charming at the same time. Wire electric can easily be installed and there is a cubby hole on the outside base to store the plug strip. Vines on the outside will easily hide the white wires.

After my boyfriend makes the elevator motor, I will make the actual elevator and install it. He works long hours so I’m not sure when it will be. He wants to 3D print a casing for it too. Until then, I will continue on and finish up my French stone cottage!

This townhouse project started when Hobby Builders Supply www.miniatures.com sent me a double room box kit!

Visit that post HERE.

this blog

this blog